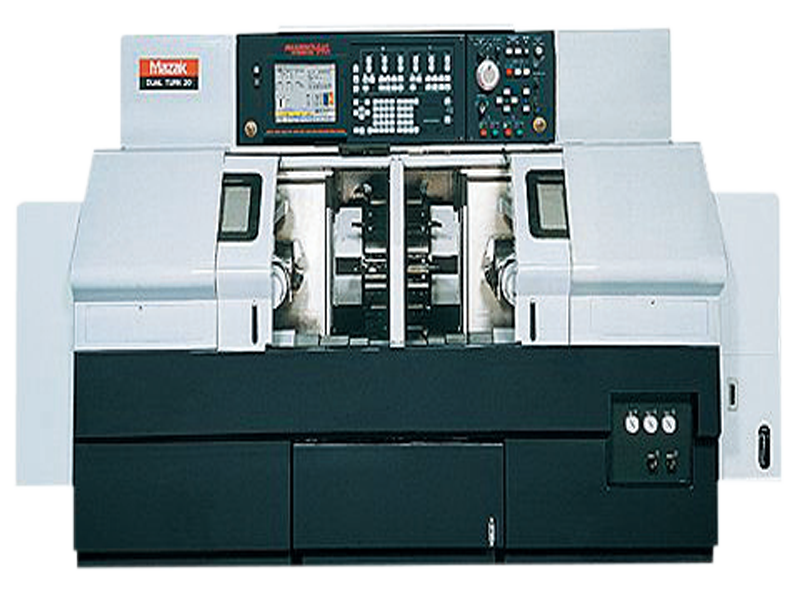

DUAL TURN 20

MACHINE DESCRIPTION:

The Dual Turn 20 utilizes 2-opposing spindles and 2 turrets, left and right, on a single machine platform for maximizing production efficiency and saving valuable manufacturing floor space. The integral spindles provide high speed turning and part transfer from spindle to spindle. Matching non-lift, 12-station turrets allow for maximum flexibility of tool layout and simultaneous operations. Factory automation unloader or load and unload gantry cell, offers unattended manufacturing operations.

MACHINE CHARACTERISTICS:

- Rock Solid design covering a wide variety of turning applications

- Mazatrol Conversational language simplifies programming of 4-axis machining

- Low cost factory automation equipment to preform unattended operations

Machine Specifications

| Specification | Bed Length - | |

|---|---|---|

| Capacity | Maximum Swing | 320 mm / 12.60 in |

| Maximum Machining Diameter | 320 mm / 12.600 in | |

| Maximum Bar Work Capacity | 51 mm / 2.0 in | |

| Maximum Machining Length | 150 mm / 5.910 in | |

| Main Spindle | Chuck Size | 8 in |

| Maximum Speed | 4750 rpm | |

| Motor Output (30 minute rating) | 15 kw / 20.0 hp | |

| Second Spindle | Chuck Size | 8 in |

| Maximum Speed | 4750 rpm | |

| Motor Output (30 minute rating) | 15 kw / 20.0 hp | |

| Turret (Upper) | Number of Tools | 12 |

| Feed Axes | Travel (X Axis) | 230 mm / 9.06 in |

| Travel (X2 Axis) | 230 mm / 9.06 in | |

| Travel (Z Axis) | 500 mm / 19.69 in | |

| Travel (Z2 Axis) | 500 mm / 19.69 in | |